pixels+atoms

Sunday, January 9, 2011

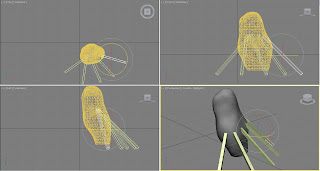

Putting Head Joint together

Using compound, the pieces of the head joint (ball, pole and head) are united to form the full head piece.

Hollow Head

The head needed to be hollowed out to allow for ball and socket joint and to minimise cost of printing. Done with a series of spheres.

Rotating Head

Decided to use a ball and socket joint to enable the head to rotate on two axes.

Firstly copied the head and then cut off the old one. Secondly, cut into the body segment with a sphere to create one part of the joint. Create another sphere inside for the other part of the joint, the second sphere is .4mm smaller.

Firstly copied the head and then cut off the old one. Secondly, cut into the body segment with a sphere to create one part of the joint. Create another sphere inside for the other part of the joint, the second sphere is .4mm smaller.

Thursday, January 6, 2011

Concept

Developing a concept to recreate an owl figure. From the bottom up the texture is created by 'formwork' shapes to give the feeling that the object is a building under construction. From the top down the object has an organic texture, feathered to represent a 'natural' object. Points of intersection show an 'impossible' meshing of materials, with feathers growing of steel. It is unclear whether the 'constructed' is taking over the 'natural' or the 'natural' consuming the 'constructed'.

A ball and socket joint allows the head of the owl to turn 360%, as in real life.

Subscribe to:

Posts (Atom)